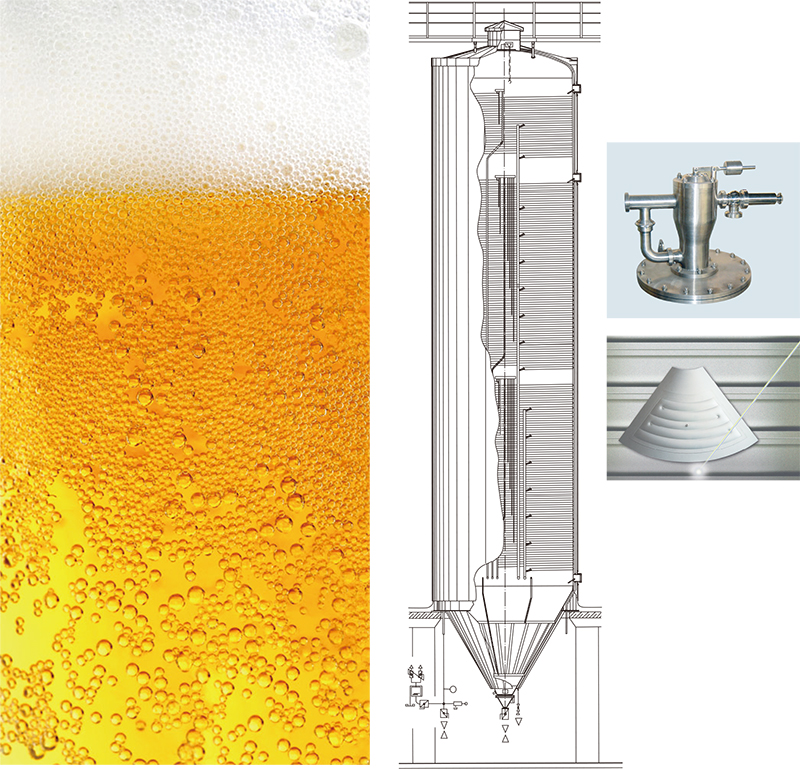

发酵的核心设备—发酵罐,从罐体径高比、冷却夹套的结构及布局、发酵罐底小锥底装置及罐顶卫生清洗安全装置的设计、制作及安装,无不体现卫生、冷媒传热及发酵液对流良好的工艺理念。在罐体径高比、冷却夹套的结构及布局方面,从理论上建立了三差理论 ( 温度差、麦汁浓度差、CO2 浓度梯度差 ) 发酵动态数学模型,用来优化发酵罐的相关结构设计;保证了温度控制、酵母的发酵及沉降分离;优化温度自控动态数学模型;保证了清洗卫生、压力安全的工艺及安全要求。

In the core equipment for fermentation--fermenting tank, the diameter-height ratio of the tank body, the structure and layout of the cooling jacket, and the design, manufacturing and installation of small conical bottom device at the bottom of the fermenting tank and the cleaning safety device at the top of the tank, all of which represent sanitation coolant heat transfer, and good technological concept of convection of fermenting liquid. With respect to the diameter-height radio of the tank body and the structure and layout of the cooling jacket, the three-difference theory (temperature difference, concentration difference, CO2 concentration gradient difference) fermenting dynamic mathematical model has been established to optimize relevant structural designs of the fermenting tank; the temperature control and fermentation and separation of yeast are ensured; the temperature automatic control dynamic mathematical model is optimized; cleanliness and sanitation are ensured and pressure safety technological and safety requirements are met.