描述

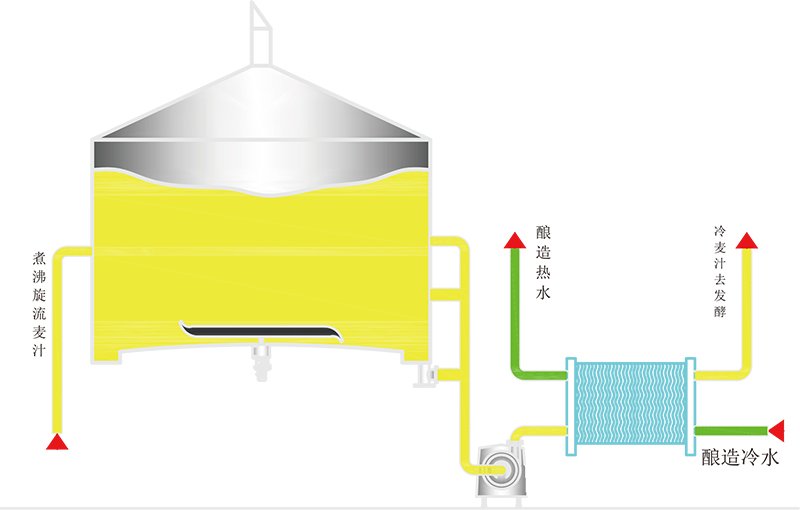

麦汁进口的结构改进及工艺效果:

麦汁进口的速度优化设计及进口位置与锅壁切线的夹角改进设计,对麦汁旋流的推动力保持、颗粒状蛋白质凝固物的完整保留及旋流分离效果有很大的改进提高;

酒花糟的干排改进及工艺效果:

旋流槽底干排糟装置的设计,实现了蛋白质凝固物及酒花糟的干排放及自清洗,大大地节约了用水量,更好的回收此蛋白质凝固物及酒花糟作为饲料,同时减少了污水的排放。

地球柯氏力影响的理论研究:

地球自转而产生的柯氏力,对麦汁凝固物颗粒的旋流分离效果有一定的影响,通过我们的研究,要求麦汁进口的旋转方向与柯氏力的方向要一致叠加,才能将更微小的颗粒分离出来。

Structural improvement of wort inlet andtechnological effect:

The speed optimized design of the wort inlet and the improved design of the included angle between the inlet point and pot wall tangent are very helpful for the improvement of the retention of wort whirlpool driving power, full retention of granular protein coagulation and whirlpool separation effect.

Improvement of dry removal of spent grains and technological effect:

The dry removal device at the bottom of the whirlpool tank is designed to realize dry removal of protein coagulation and spent grains and selfcleaning, which greatly saves water consumption, recycles the protein coagulation and spent grains as feedstuff and reduce emission of sewage at the same time.

Theoretical research of the impact of Coriolis force:

The Coriolis force produced by rotation of the earth has a certain impact on the whirlpool separation of wort coagulation granules effect. Through our research, the finer granules can be separated only when the rotation direction of wort inlet is the same as that of Coriolis force.

上一篇

麦汁煮沸及酒花添加单元

糖化热能回收单元

下一篇