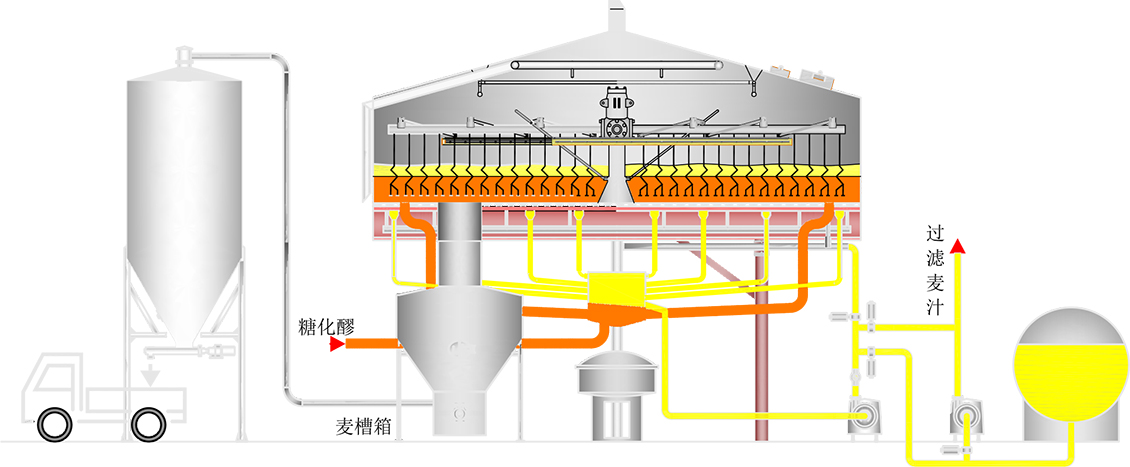

描述

过滤槽重点技术:

糖化的批次高低关键看过滤槽;华艺公司对过滤槽从宏观到每一个细节都做了研发改进设计;特别是“结合糖”的快速溶出做了大量的理论研究和实验,建立了一系列的数学模型,突破了一些列技术难题。使过滤速度提上新的台阶。可以把全部过滤操作时间控制在 2 小时以内。

技术突破点:

① 过滤动态控制数学模型:通过巧妙的自控检测手段来反馈出麦汁浊度、流速及糟层阻力,控制适当的过滤流量、耕刀转速及升降高度,以保证原麦汁从开始至终都保持顺畅,或及时进行必要的糟层处理。

② 过滤耕刀结构及“内洗糟”技术的改进:特殊的恰到好处的耕刀设计结构,对改善糟层的渗滤性有很大的提高。洗糟速度、强度及时间影响麦汁的过滤效率、有害物质的浸出及氧化作用。特别是“内洗糟”技术的应用,使得糟层中“结合糖”的快速溶出对过滤速度的提高,做了大量的理论研究和实验,建立了一系列的数学模型,并得到工程案例的验证。

③ 筛板底“相控阵”清洗系统:板底泥状物若清理不干净会影响下一锅次麦汁过滤质量及速度。清洗喷嘴独特结构的应用,使得喷射角度相互覆盖,整体“相控阵”布局,使得无清洗死角,不再用人工拆洗筛板,减少劳动强度及筛板的变形。

Key technology of fi lter tank:

The quality of saccharifying depends on the filter tank. Huayi Company has made R&D and improved design from macroscopic aspect to all details. A great number of theoretical researches experiments have been carried out according to the fast dissolving of sugar, and a series of mathematical models have been established, which fi nally solved the technical problem to enhance the fi ltering speed to a new height. The whole filtering operation can be controlled within 2 hours.

Technical breakthroughs:

① Dynamic control mathematical model of fi ltration: The wort turbidity, fl ow rate and grain layer resistance ,proper fi ltering fl ow control, raker revolving speed and lifting height, are fed back through the master automatic control inspection means to ensure the wort to maintain smooth from the beginning to the end or execute necessary grain layer treatment timely by controlling the appropriate leaching fl ow, raker revolving speed and rise and fall height.

② Improvement of fi ltering raker and inner washing grain technology:

The special raker structure designed to a nicety is very helpful for the improvement of percolation property of the grain layer. The grain washing speed, intensity and time will influence the filtering efficiency of wort, leaching of harmful substances and oxidation. Especially, the application of washing tank technology makes the rapid digestion of the combined saccharides increase the fi ltering speed. A great number of theoretical researches and experiments have been carried out, and a series of mathematical models have been established, which is verifi ed by project cases.

③ Improvement of the cleaning system at the bottom of the sieve plate:

Incomplete cleaning of the mud-like stuff at the bottom will affect the fi ltering quality and speed of wort in the next pot. The special structure of the cleaning nozzle makes the spraying angles mutually overlapped. The total phased array layout guarantees the leaning has no dead corner left and there is no need to disassemble the sieve plate for cleaning manually, which would reduce the labor intensity and the deformation of the sieve plate.

上一篇

糊化糖化单元

麦汁煮沸及酒花添加单元

下一篇