描述

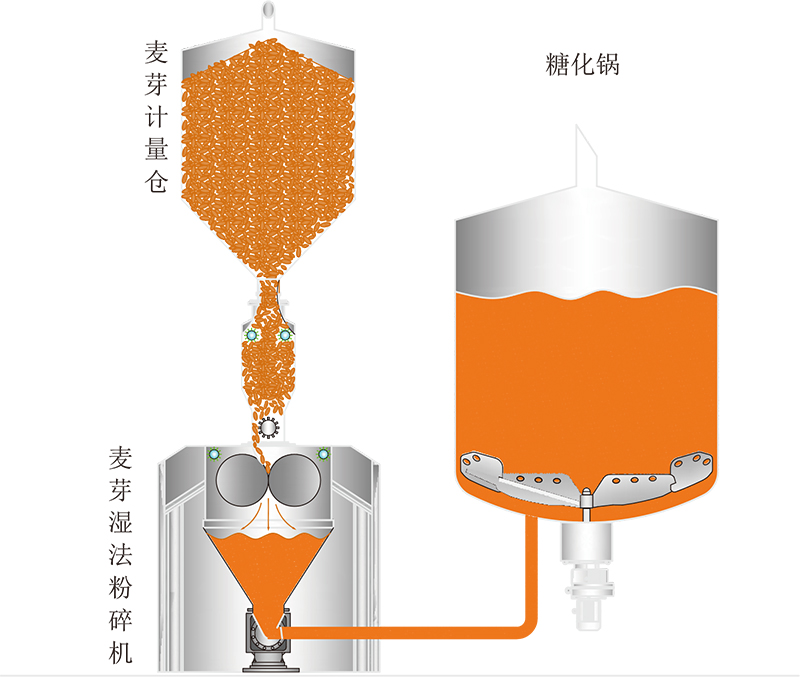

原料粉碎方式:

原料粉碎方式:

有湿法粉碎和回潮粉碎二种工艺。

湿法粉碎方式:

使麦芽吸水后粉碎,提高麦皮的完整度,提高单位过滤面积的投料承载力,可以送入CO2隔氧,进醪速度和混合的均匀性。但瞬间动力负荷大,粉碎时间要求严格。

回潮增湿粉碎:

麦芽吸收水分均匀可调,能最大限度地确保粉碎后麦芽皮壳的完整度,粉碎后的物料可以短时间的贮存,有利于调节粉碎与投料时间的衔接,不需要太大的粉碎能力,瞬间粉碎动力负荷小。

原料粉碎要求:

满足生产效率的要求,粉碎麦芽的麦皮尽可能完整(提高过滤槽的渗透性,减少有害成分浸出);淀粉原料的粉碎度达到一定的要求(便于糊化及 α- 淀粉酶的快速分解)。

原料控制要求:

准确可靠的料水比、pH 在线调节,通过变频控制搅拌速度,自动化控制。

Raw materials milling mode:

Including wet milling and moisture regain milling.

Wet milling:

The milling is carried out after the malt absorbs water, so that the bran integrity is enhanced and the feeding bearing capacity on unit filtering area is improved. CO2 can be fed to isolate oxygen, improving mash charging speed and evenness of mixing. The instantaneous power load is high, so the requirement for milling time is high.

Moisture regain milling:

The moisture absorption by the malt is even and adjustable, so that the bran integrity can be maintained to the utmost extent after milling.

The materials after milling can be stored for a short period of time, which is beneficial to the connection of milling time and feeding time. The milling capacity is not required to be very high and the instantaneous power load is low.

Raw materials milling requirements:

To meet the requirement for production efficiency, the bran shall be integral whenever possible (enhancing the penetration of filter tank, and reducing leaching of harmful contents). The milling degree of starch raw materials shall meet certain requirements (for the convenience of gelatinization and rapid decomposition of α-starch).

Raw materials controlling requirements:

Accurate and reliable material water ratio, pH online adjustment, controlled through frequency converter, automatic control.

上一篇

原料输送单元

糊化糖化单元

下一篇